As we already know, grinding, the final stage of mechanical machining, consists in the finishing applied to a detail through the removal of surface material. The optimal result of this process is achieved using advanced and innovative tools. Indeed, since the introduction of Face Drivers into our machining systems In 1985, we guarantee excellent results in grinding, completing precision work in one single step.

One of the advantages of employing our face driver rather than diametrical gripping systems with a mandrel or chuck, is that a piece can be worked without having to finish the detail separately, and thanks to a system of self-compensation of the extremely sensitive claws, it is possible to achieve a high degree of concentric precision, complete reliability, systematic repeatability of the results and unrivalled grip capacity on the piece to grind.

The perfect synergy between our sales network and technical office means that the client is supplied with the best possible solution to fit his requirements, using advanced 3D CAD systems.

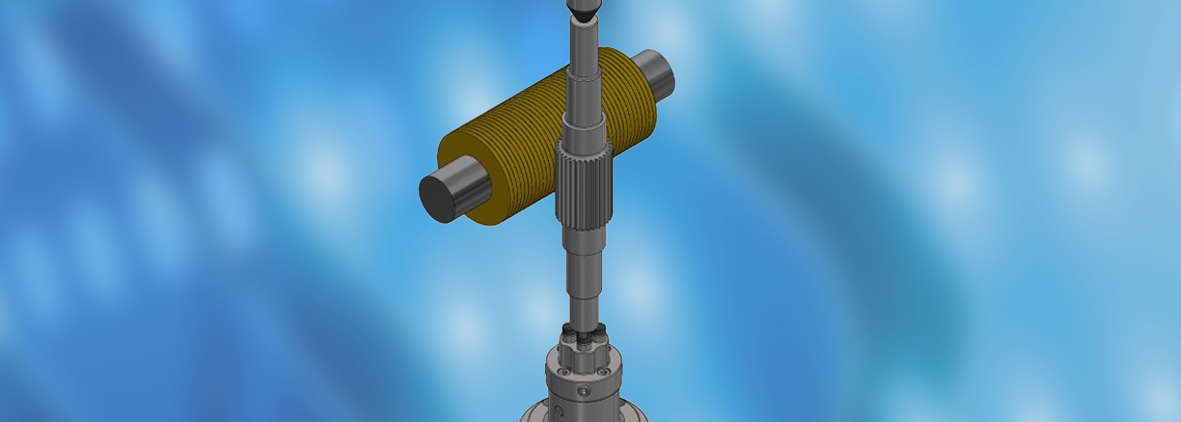

Along with face drivers, we also offer series 92 center points, within which 5 carefully selected bearings are installed and adapted for the shaft and barrel, which ensure a high precision finish with a maximum roundness and concentricity error of 0.0015 and 0.0025 respectively.