Our company, FRB, set down its roots in the early sixties. Its history is based on dedication, research, hard work and passion and the leading man is Romano Franceschelli. First as a turner, then as a mechanical designer and lastly an engineer, it is Romano who steered the company’s growth based on solid values. First and foremost, the values of teamwork and reliability.

The values instilled by its founder characterises FRB to this day. The sense of family, the sharing of each challenge and a common vision based on sociability and the desire to discover innovative solutions, are what makes the FRB team unique and efficient. These important human values are reflected in the work of each and every member of our staff, creating a high quality company system, which is successful not only in terms of productivity but also in terms of relationships.

This is what really makes FRB stand out, over and above the high level of technical competence and a natural inclination towards the search for innovative solutions. It is another legacy handed down by Romano.

These are the characteristics which have contributed to the constant growth of FRB right up to the present day. In our plant in Sasso Marconi (Bologna) today, highly qualified staff have a modern, technologically advanced system at their disposal. Our technicians collaborate with the engineering departments of the most important machine tool manufacturers in Italy and abroad, enjoying the trust of key players to whom we offer not only our tools but also our know-how regarding the optimisation of work cycles in turning and grinding.

This is what really makes FRB stand out, over and above the high level of technical competence and a natural inclination towards the search for innovative solutions. It is another legacy handed down by Romano.

These are the characteristics which have contributed to the constant growth of FRB right up to the present day. In our plant in Sasso Marconi (Bologna) today, highly qualified staff have a modern, technologically advanced system at their disposal. Our technicians collaborate with the engineering departments of the most important machine tool manufacturers in Italy and abroad, enjoying the trust of key players to whom we offer not only our tools but also our know-how regarding the optimisation of work cycles in turning and grinding.

Team

Cohesive and highly specialised but at the same time flexible and open to innovation.

Quality

We work hard to dedicate our Competence and Experience to our customers.

Solutions

Our desire is to go beyond the purely mechanical problem, in order to identify the best possible solution.

Quality control

Our internal monitoring procedure guarantees the strict respect of characteristics and requisites.

Efficency

Our competence and the optimal management of our departments render the process highly efficient, thereby lowering work times and costs.

Assistance

Our flagship. FRB invests continually in order to guarantee its customers a high level of assistance.

OUR HISTORY

1965

Foundation

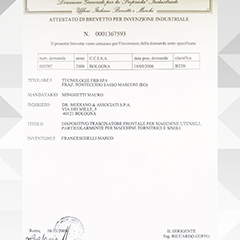

1964-1968

Filing of the first patents

1976

Headquarter Tecnologie FRB

1985

New development of front face drivers

2001

Technical office switches to CAD systems

2005

The management passes to Marco and Patrizia

2006

Foreign development thanks to international fairs

2011

ISO 9001 Certification and quality control renewal

2015

Investments in production and design equipment

TODAY

Continuous growth and evolution

Production

If we had to describe the production system of FRB in one word, the best term would be Reliability.

Reliability of the product itself, of delivery, of the services we offer and in the response times necessary for any request or requirement. These are the cornerstones on which FRB has based its production.

The reliability of a technical solution and as a consequence, of a finished product, is undoubtedly linked to innovation. Innovation linked, in turn, to technological evolution within the sector, to the different manufacturing processes which characterise each of FRB’s clients, which, in turn, implement changes.

Tecnologie FRB has a completely autonomous production capacity with manufacturing, quality control and storage departments.

With our new state of the art machines, such as, for example, the twin-spindle lathes with three automatic tool changers (18 tools) and bar feed, our turning and milling departments are able to carry out complex machining aimed at producing detailed pieces using multitasking units and rotating tools supported by design and programming with CAD-CAM.

In our grinding department, fitted out with state of the art machinery such as multi spindle machines for external and internal machining, all at the same work station, we can fully satisfy production and manufacturing requirements, completing the necessary geometrical figures while respecting both form and size tolerance.

All of this in an air conditioned measuring room with 4 axis 3D control and a certified involute measurement machine, instruments and calibers for supervision during production and post - manufacturing, with the issue of the relative test certificates.

Last but not least, the use of a fully automated warehouse system for the rationalisation of internal logistics and of material management stock control. Each area is developed with complete respect for the environment and to this end, we have had a photovoltaic system fitted over the last few years to provide autonomous production of the energy necessary for the running of our company.

We have not achieved all of this from pretention or because it heightens our work, but because this is what we, in turn, look for in a Supplier.

Tecnologie FRB has a completely autonomous production capacity with manufacturing, quality control and storage departments.

With our new state of the art machines, such as, for example, the twin-spindle lathes with three automatic tool changers (18 tools) and bar feed, our turning and milling departments are able to carry out complex machining aimed at producing detailed pieces using multitasking units and rotating tools supported by design and programming with CAD-CAM.

In our grinding department, fitted out with state of the art machinery such as multi spindle machines for external and internal machining, all at the same work station, we can fully satisfy production and manufacturing requirements, completing the necessary geometrical figures while respecting both form and size tolerance.

All of this in an air conditioned measuring room with 4 axis 3D control and a certified involute measurement machine, instruments and calibers for supervision during production and post - manufacturing, with the issue of the relative test certificates.

Last but not least, the use of a fully automated warehouse system for the rationalisation of internal logistics and of material management stock control. Each area is developed with complete respect for the environment and to this end, we have had a photovoltaic system fitted over the last few years to provide autonomous production of the energy necessary for the running of our company.

We have not achieved all of this from pretention or because it heightens our work, but because this is what we, in turn, look for in a Supplier.

1300

sqm. of production area

12

machine tools

7

specialised technicians

2

vertical warehouses

Our partners